What Glue To Use To Repair Cracked Wood

Repairing Wood: How to Make Potent Glue Joints in Woods

How to gum wood joints that are stronger than the wood itself.

Repair broken article of furniture and cracked woodwork, make stronger woodworking projects, and larn how to make cleaner, tougher glue joints with these gluing tips and techniques.

You might also like: TBD

Use tape to command mucilage clasp-out

How to Fix Cracked Wood: Use tape to clamp cracked forest

It's often tough to repair cracked cabinets and article of furniture with regular clamps. But transparent record makes a great substitute. If the wood is just cracked, flatten the end of a drinking straw and blow the glue into the crack. So tape it.

If a slice has broken off, follow Photos i and two. One drawback: Super-viscid tape can pull off finishes and paint when you remove it. Use light-duty tape or attach regular tape lightly. And remove information technology as soon every bit the glue dries.

Make clean and clench when re-gluing a chair

Regluing a chair is challenging because you unremarkably accept to at to the lowest degree partially disassemble the chair and mucilage the aforementioned joints all over over again. One disquisitional pace is to clean off every bit of the old gum. There will exist quite a chip of it, since you'll probably have several loose joints and may have to knock others autonomously to disassemble the loose ones. You have to make clean both the dowel terminate (Photo 1) and the socket (Photo 2). The trick is to practise it without digging into the woods. The more than forest you shave abroad, the larger the gaps that the new glue volition have to fill. Use sandpaper but as a last resort, because it tends to sand away wood as well as glue.

You'll observe the steel brushes for cleaning the sockets (Photo 2) in the plumbing section of a dwelling middle or hardware store. They're designed to clean the insides of copper pipe and fittings and are available in several sizes.

Clamping may call for inventiveness (Photo 3). The play tricks is to first dry-fit all the parts you intend to glue at one time. If possible, mucilage the chair in 2 stages: the seat and legs first, so when they're dry, the backrest section. Test-fit the clamps to brand sure where every clamp will get. And so you lot can work swiftly when applying the glue. Yet, employ liquid hide glue rather than yellow glue; hide gum gives a much longer open time before "grabbing," so you tin can get all the parts and clamps in place.

Add together glue blocks

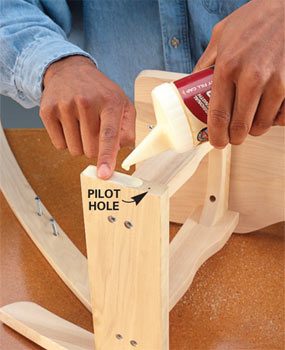

Glue and screw whenever possible

Screws are ideal for joints that call for extra strength, or where accurate positioning of a glued piece would be difficult.

Insert gum biscuits to double articulation forcefulness

They may not be good to eat, but gum biscuits are the exercise-it-yourself cabinetmaker'south best friend. A biscuit joiner (Photo 1) is very user friendly and uncomplicated to operate. Information technology cuts precise oval slots in the ends and the surfaces of wood parts that enable y'all to position the parts for clamping and gluing apace and accurately. The glued-in-place biscuits provide broad gluing surfaces that brand for a strong articulation. A special glue bottle (Photo 2), available from woodworking suppliers, speeds upwards the application of glue and distributes it evenly in the slots. Don't delay during glue-upwards! Biscuits swell subsequently gluing (which adds to their strength), so yous don't accept much time for associates. Preassemble with dry biscuits to check fits—you won't get a 2nd run a risk.

Spread glue evenly on big areas

Reminders for strong glue joints

- Make sure your gluing surfaces are make clean and smooth just not too glossy. Crude surfaces don't allow enough glue contact. Glossy surfaces forbid the mucilage from penetrating the fibers and getting a good grip. You tin can sand lightly to smooth roughness or remove gloss, but don't attempt to actually shape a joint past sanding; it's impossible to get a proficient mating fit that way. If y'all're sanding, use a block and exist conscientious non to circular over precipitous edges.

- Clamp all glued joints. Pressure is necessary to grade a tight, gap-free bond, and to help force gum into the woods fibers. Clamping also prevents movement while the glue is hardening. In situations where you lot can't use clamps, use screws, elastic cords or weights.

- Do a dry out run with clamps before you employ whatever gum. This not only allows y'all to check for a adept fit but as well ensures that yous will take your clamps adjusted to proper length, and all other necessary tools at the set up. It'southward important to complete a glue-up adequately speedily; fifty-fifty though it takes about an hour for almost forest glues to ready and 24 hours to cure, the initial "catch" takes identify in two or 3 minutes, and clamping should exist completed by then.

- Become a proficient fit between the two glued surfaces. Wood glues (except for epoxy) won't bridge gaps, and so any joint with gaps will exist weak. The parts should fit together snugly. If you tin can't reshape the part with a router or table saw, try gluing thin wood curls in place to make full the gaps. (You can cut curls from a scrap board using a wood aeroplane.)

Choose the best type of glue

Required Tools for this Project

Have the necessary tools for this DIY project lined up before y'all start—you lot'll salve time and frustration.

Yous'll also need a gum spreader, a biscuit-slot gum tip, a circular wire castor, and elastic cords.

Required Materials for this Project

Avoid terminal-minute shopping trips by having all your materials ready ahead of time. Here'south a list.

Source: https://www.familyhandyman.com/project/repairing-wood-strong-glue-joints-in-wood/

Posted by: doughtyvased1986.blogspot.com

0 Response to "What Glue To Use To Repair Cracked Wood"

Post a Comment